Mill and Overlay Over Milled Surface

When it comes to asphalt overlays, there is a lot to take into consideration. Not all asphalt roads and parking lots are good candidates for an overlay. The reason? Drainage, drainage, drainage.

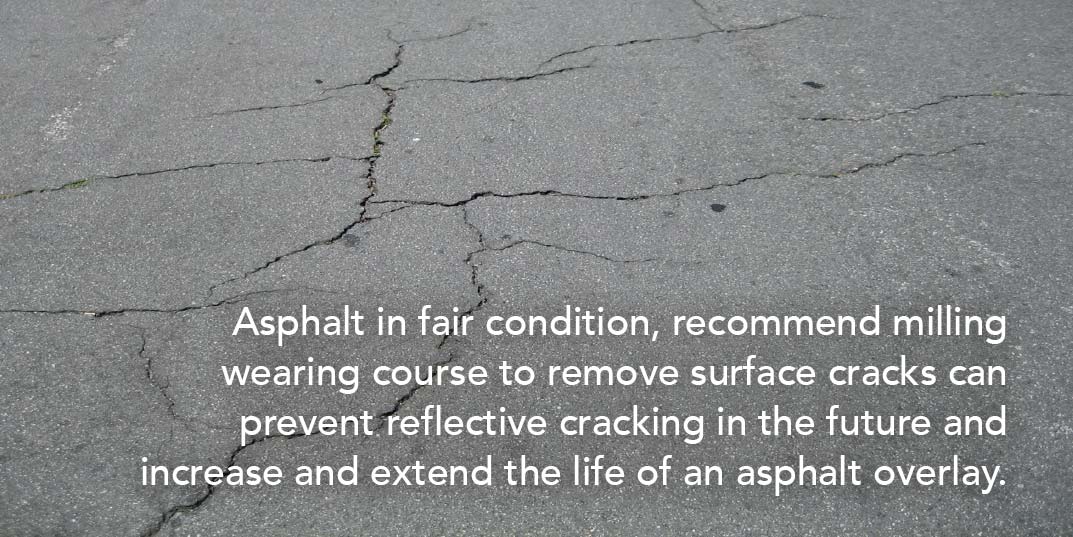

When overlaying existing asphalt, current drainage patterns may be disrupted, causing water to not drain properly. But, if a property has minimal slopes and drainage issues, a mill and overlay over milled surface will be a viable option in most cases. Milling the wearing course can remove minimal fatigue cracks from the surface while maintaining the existing elevations and drainage flow patterns.

Preparation is key to a successful asphalt overlay project.

Transition Grinding

– At all concrete abutments and at flow lines.

To maintain asphalt thickness and improve drainage at transition points.

Treat All Failures

– Prior to overlay, sweep, clean and remove all debris thoroughly prior to tacking the surface.

The correct asphalt thickness for a proper overlay is a minimum of a 1.5” to 2” of new hot mix asphalt, and must be properly compacted.

If the existing condition of the asphalt is not too far gone, and all preparation steps are completed, an asphalt overlay can help improve the structural integrity of the surface, minimize risks and enhance the property’s appearance.